In the modern medical landscape, the choice of Personal Protective Equipment (PPE) has evolved from a simple logistical decision into a strategic priority that impacts patient safe...

READ MORE

Medical knitting refers to the application of knitting technology and techniques in the healthcare sector to create specialized, functional textiles.

In the modern medical landscape, the choice of Personal Protective Equipment (PPE) has evolved from a simple logistical decision into a strategic priority that impacts patient safe...

READ MOREIn the intricate world of modern surgery, maintaining a sterile field is not just a best practice---it's a critical determinant of patient outcomes. At the heart of this aseptic pr...

READ MOREIn the evolving landscape of precision medicine, the integration of Medical Knitting Textiles into surgical implant applications represents a pinnacle of textile engineering. Unlik...

READ MOREThe global healthcare system relies on a vast and often unseen arsenal of single-use products. These disposable medical consumables form the frontline of infection control, patient...

READ MOREIn the world of healthcare, the textiles we wear or apply to our bodies are far more than simple fabrics. They are engineered materials designed to serve specific medical purposes. This is where medical knitting textiles come in. Unlike traditional woven fabrics, which are created by interlacing two or more sets of yarns at right angles, knitted textiles are formed by a series of interlocking loops. This unique structure gives them properties that are highly advantageous in medical applications: they are flexible, breathable, elastic, and can be easily shaped to conform to the body’s contours.

The history of medical textiles is a long one, but the integration of advanced knitting technology has propelled this field into a new era of innovation. The ability to precisely control the knit structure allows manufacturers to create products with specific functionalities. For instance, varying the tension and type of yarn can produce a fabric with graduated compression, which is crucial for treating conditions like deep vein thrombosis (DVT). Similarly, using a specific type of yarn can make the textile antibacterial or even capable of delivering medication directly to the skin.

The applications of these textiles are vast and varied, touching almost every aspect of patient care. We can broadly categorize them into several key areas:

The effectiveness of medical knitting textiles is rooted in their unique structural properties. The interlocking loop structure provides a level of elasticity and stretch that is difficult to achieve with woven fabrics. This is particularly important for products that need to move with the body, such as orthopedic braces or compression garments. The stretch and recovery properties of knitted fabrics allow them to provide consistent pressure or support without becoming loose or uncomfortable.

Moreover, the porous nature of knitted fabrics allows for excellent air and moisture permeability. This is a critical feature for wound dressings and compression garments, as it helps to prevent skin maceration (softening and breakdown of skin due to moisture) and keeps the patient comfortable. By using different types of yarn, manufacturers can further enhance these properties. For example, some synthetic fibers can wick moisture away from the skin, while others can be infused with antimicrobial properties to prevent infection.

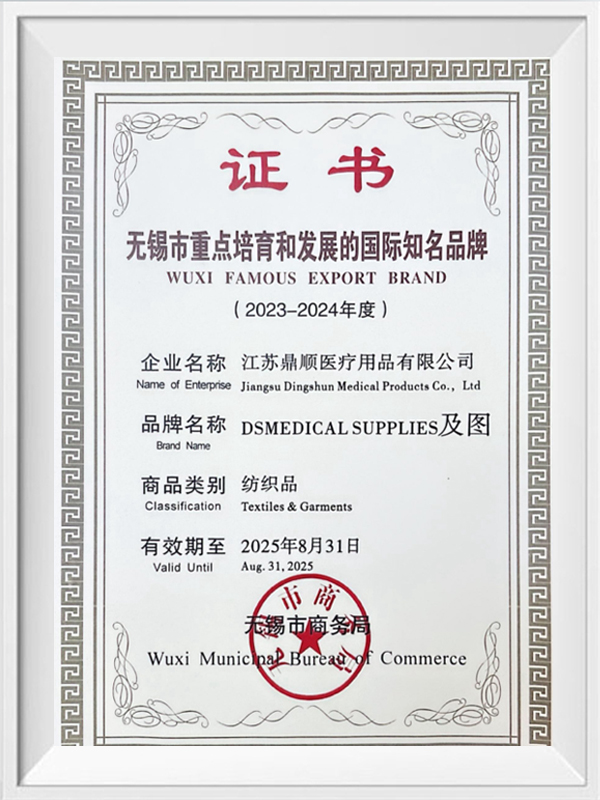

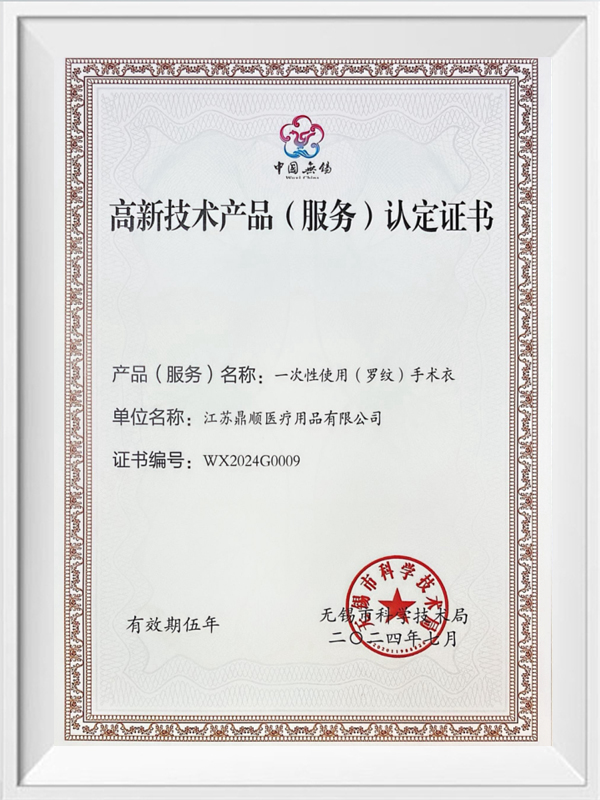

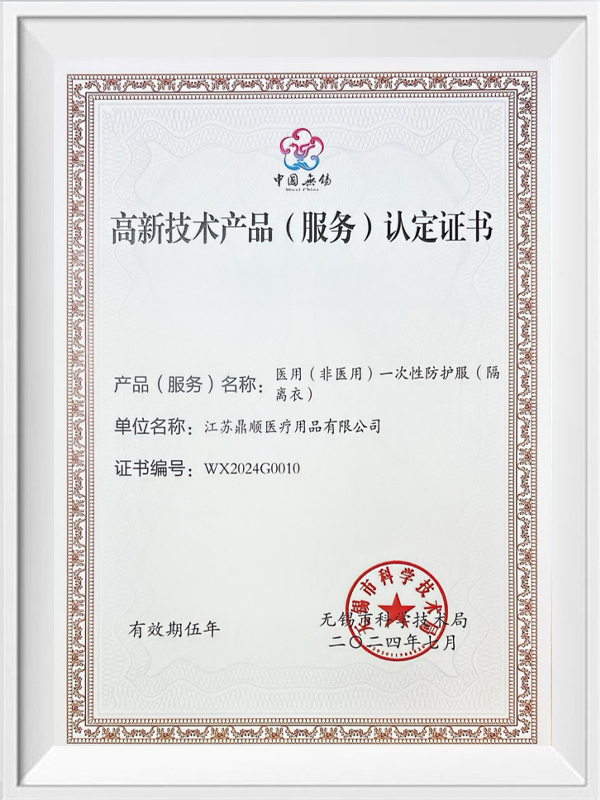

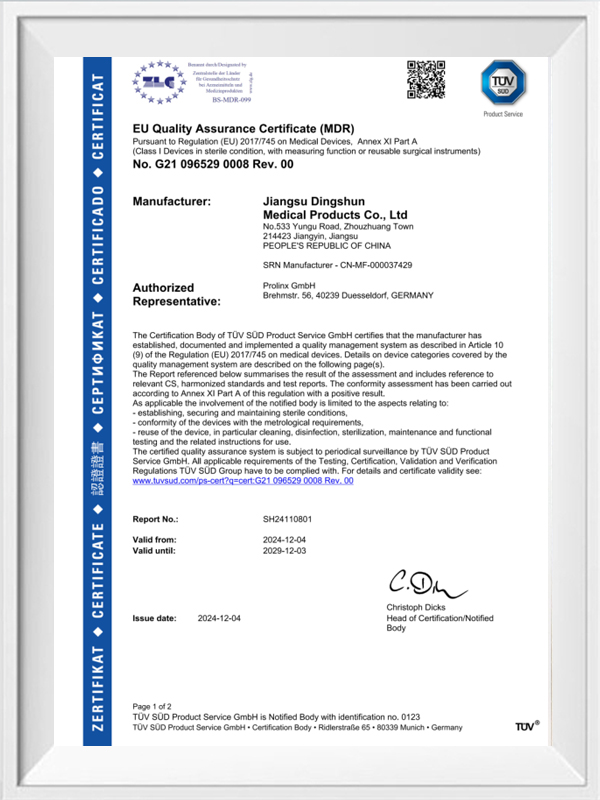

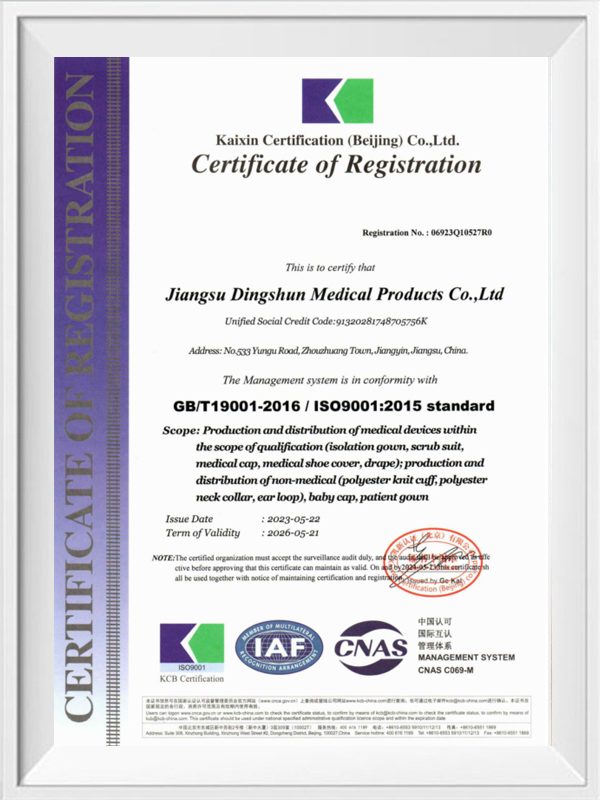

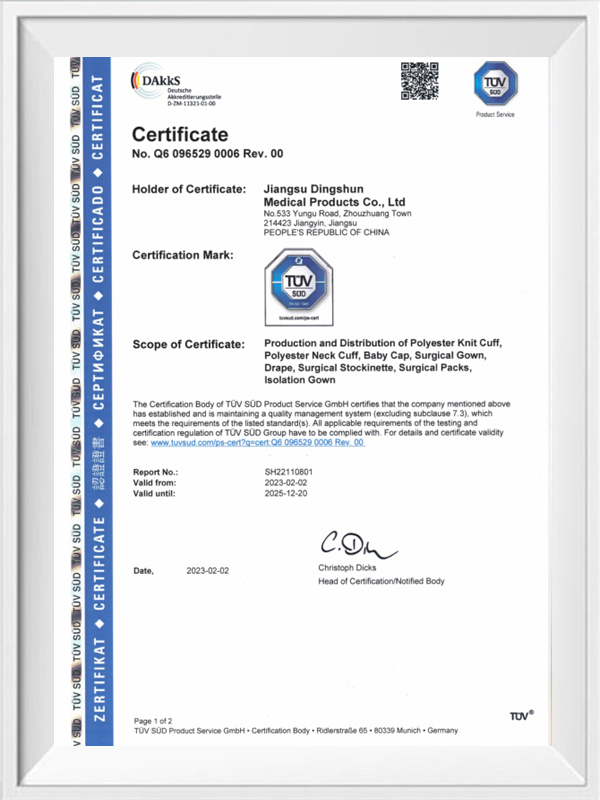

The ability to create complex 3D shapes is another significant advantage of knitting technology. Unlike woven fabrics, which are typically flat, knitting machines can produce seamless, contoured products. This is particularly useful for creating form-fitting garments like compression stockings or prosthetic socks, which need to fit perfectly to provide their therapeutic benefits. This precision manufacturing minimizes the risk of chafing and discomfort, improving patient compliance and treatment outcomes. It is this unwavering focus on precision and quality that distinguishes leaders in the field. For instance, companies like Jiangsu Dingshun Medical Supplies Co., Ltd. showcase how a deep understanding of textile science, combined with advanced manufacturing techniques, is essential for producing high-quality, reliable medical knitting textiles that doctors and patients can trust.

The future of medical knitting textiles is bright and filled with potential. Advancements in materials science are leading to the development of “smart textiles” that can do more than just provide support or compression. Imagine a knitted bandage that can sense the pH level of a wound and release an antimicrobial agent when needed, or a compression sock that can monitor a patient’s circulation and send data to their doctor. These are not science fiction; they are the next generation of medical textiles being developed today.

The demand for high-quality, reliable medical textiles is growing globally, driven by an aging population and an increased focus on non-invasive treatment methods. The continued evolution of these products, from their material composition to their functional design, will be critical in shaping the future of patient care. In conclusion, medical knitting textiles are more than just a niche product category; they are a fundamental part of modern healthcare. They represent a blend of textile engineering, materials science, and medical expertise, offering innovative solutions that improve patient comfort, accelerate recovery, and ultimately save lives. As technology continues to evolve, these textiles will play an even more critical role in the future of medicine.